Welding

It is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both forming a join as the parts cool. Welding is usually used on metals and thermoplastics but can also be used on wood. The completed welded joint may be referred to as a weldment.

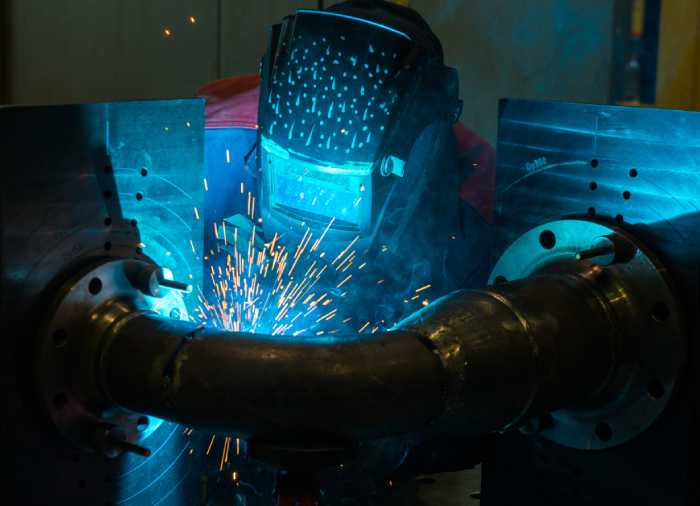

Welding is a core activity in the fabrication factory, undertaken by skilled, qualified operatives working to a welding quality management system under the control of a Responsible Welding Coordinator. It is used to prepare joints for connection in the shop and on site, and for the attachment of other fixtures and fittings. Different welding techniques are used for different activities within the fabrication factory.

Essentially, the welding process uses an electric arc to generate heat to melt the parent material in the joint. A separate filler material supplied as a consumable electrode also melts and combines with the parent material to form a molten weld pool. As welding progresses along the joint, the weld pool solidifies fusing the parent and weld metal together. Several passes or runs may be required to fill the joint or to build up the weld to the design size.

Drilling

Drilling is a cutting process that uses a drill bit to cut a hole of circular cross-section in solid materials. The drill bit is usually a rotary cutting tool, often multi-point. The bit is pressed against the work-piece and rotated at rates from hundreds to thousands of revolutions per minute.

Drilling is easily the most common machining process. One estimate is that 75% of all metal-cutting material removed comes from drilling operations.

Drilling involves the creation of holes that are right circular cylinders. This is accomplished most typically by using a twist drill, something most readers will have seen before.

Drilling is one of the machining processes, which used to make a hole on component face. Recent developments in the drilling operation showed a new trends in the hole manufacturing.

To install this Web App in your iPhone/iPad press ![]() and then Add to Home Screen.

and then Add to Home Screen.